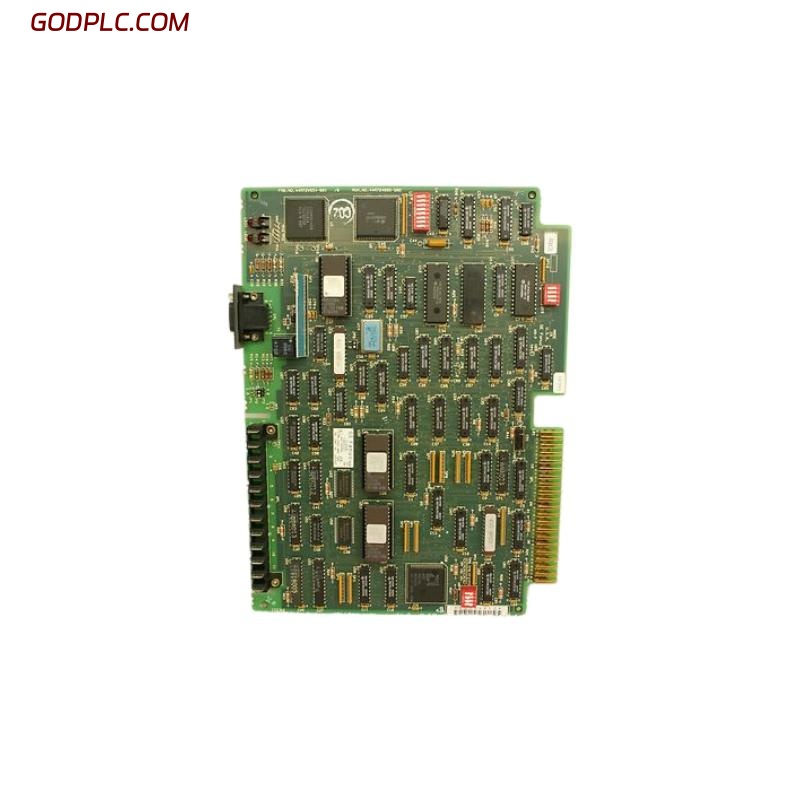

GE Fanuc IC693DSM314 Axis Motion Control Module

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

GE Fanuc IC693DSM314 Axis Motion Control Module

Product Overview

The GE Fanuc IC693DSM314 Axis Motion Control Module is a high-performance motion control solution designed to be integrated with GE Fanuc Series 90-30 PLC systems. This module provides precise control over the motion of machines, conveyors, and robotic arms, delivering accurate positioning and speed control across various industrial applications. Ideal for use in industries such as manufacturing, packaging, and material handling, the IC693DSM314 ensures seamless motion coordination, high-speed performance, and reliable operation in complex automation systems.

Key Features

-

High-Performance Motion Control – Enables precise control over multiple axes of motion, allowing for accurate position, speed, and torque control in machines and equipment

-

Multi-Axis Support – Supports up to 3 axes of independent motion control, making it suitable for multi-axis systems and applications such as robotics, packaging machines, and automated production lines

-

Positioning and Speed Control – Provides highly accurate positioning and speed control, essential for applications that require fine-tuned motion, including CNC machines and automated conveyors

-

Programmable Motion Profiles – Offers the ability to program complex motion profiles, including velocity and acceleration curves, to optimize machine performance and product quality

-

Real-Time Data – Provides real-time feedback and diagnostics, enabling operators to monitor and adjust motion parameters for optimal performance and minimal downtime

-

Seamless Integration – Designed for easy integration with GE Fanuc Series 90-30 PLCs, ensuring smooth communication and system operation across multiple modules and devices

-

Compact and Robust Design – Built to operate in demanding industrial environments, with a compact and rugged design that ensures durability and reliability in harsh conditions

-

Advanced Diagnostics – Equipped with advanced diagnostic tools to monitor the health of the motion system, detect faults, and support preventive maintenance efforts

-

Flexible Configuration – Supports a variety of motion control configurations, including stepper motors, servos, and DC motors, providing flexibility for diverse applications

-

Enhanced Motion Profiling – Allows for advanced motion functions such as jerk-limited acceleration and deceleration, helping to reduce mechanical wear and tear

Technical Specifications

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | 130 x 100 x 30 mm |

| Weight | 0.5 kg |

3.2 Electrical Characteristics

| Item | Specification |

|---|---|

| Input Voltage | 5 VDC (nominal) |

| Power Consumption | Approx. 4 W |

| Output Type | Differential (for motor control) |

| Output Current | 1 A (max per axis) |

| Communication | RS-485 or Ethernet (depending on configuration) |

3.3 Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temp | -20°C to +60°C |

| Storage Temp | -40°C to +85°C |

| Humidity | 5%–95% RH (non-condensing) |

| Vibration | IEC 60068-2 compliant |

| Protection | IP20 (when installed in an enclosure) |

3.4 System Compatibility

| Item | Specification |

|---|---|

| Platform | GE Fanuc Series 90-30 |

| Compatible Modules | GE Fanuc I/O modules, motion controllers, and expansion modules |

| Supported Motors | Stepper, DC, and servo motors |

Industry Applications

-

Manufacturing – Ideal for controlling automated production lines, including conveyors, robotic arms, and CNC machines, enabling precise motion and positioning for increased productivity and reduced errors

-

Packaging – Used in packaging systems to control motion of machines like labelers, sorters, and filling stations, ensuring high-speed, accurate operations and high product throughput

-

Material Handling – Enhances material handling systems by providing precise control over conveyors, sorters, and automated guided vehicles (AGVs) for improved operational efficiency and safety

-

Robotics – Supports multi-axis motion control in robotic systems, ensuring precise and coordinated movements for tasks such as assembly, pick-and-place, and inspection

-

Automated Assembly – Enables accurate motion control in automated assembly systems, ensuring precision assembly and minimizing errors in high-volume manufacturing environments

The GE Fanuc IC693DSM314 Axis Motion Control Module provides high-performance motion control for industrial applications requiring precise coordination and speed. Its multi-axis capability, advanced diagnostics, and seamless integration with GE Fanuc PLCs make it ideal for industries like manufacturing, packaging, robotics, and material handling. By offering accurate positioning, flexible motor control, and real-time data feedback, the IC693DSM314 ensures the efficient and reliable operation of automated systems, reducing downtime and improving overall system performance.

GE Fanuc IC693DSM314 Axis Motion Control Module is in stock. Please contact us for a quick quote and competitive pricing.

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Company Introduction

Xiamen Shengruite Trading Co., Ltd. is a company specializing in the supply of industrial PLC spare parts.

We provide high-quality PLC spare parts to customers in the global manufacturing, energy and power, chemical and other fields.

Since its establishment in 2011, after 13 years of rapid development, the cumulative global shipments have reached 223,650 pieces, with an annual output value of US$50 million.

Successfully served more than 500 customers in more than 100 countries and regions including Saudi Arabia, UAE, the United States, Europe, Africa, and Southeast Asia

Our Mission

Provide customers with the best quality PLC spare parts and the fastest delivery service to ensure that their industrial automation systems are always in the best operating condition.

We provide a 1-year warranty service, and we support returns and exchanges for any issues to ensure your rights and interests are fully protected.

We can provide detailed product images upon request, and our team can arrange warehouse photos for confirmation to ensure you have all the information you need before making a purchase.

Shipping times vary depending on your location. With the support of our 16 global warehouses, we strive to deliver orders as quickly as possible. Contact us to get an estimated delivery time for your specific location.

The minimum order quantity (MOQ) is typically one unit. However, for larger orders, please contact us for potential discounts and pricing details.

Yes, we offer competitive pricing for bulk purchases. Please reach out to our sales team with the specifics of your order to receive a custom quote.

We accept various payment methods for wholesale orders, including bank transfers (T/T), letters of credit, and other options upon agreement. For large transactions, please contact us directly for payment terms.

Yes, we offer flexible ordering options for both small and large quantities. Whether you\\\\\\\\\\\\\\\’re looking for a single unit or a large batch, we can accommodate your needs.

We occasionally offer promotional discounts for new wholesale customers. Contact us to learn more about any current offers available for first-time buyers.

If you are unsure of compatibility with your existing setup please provide your system details and our support team can verify compatibility prior to purchase.

Returns are accepted within 30 days if the product is unused, unopened, and in its original packaging. Please note that return shipping and associated costs are the buyer\\\\\\\\\\\\\\\’s responsibility.

Yes, we offer technical support for the installation and integration of our products. Our team can assist with setup, configuration, and troubleshooting to ensure a smooth installation.