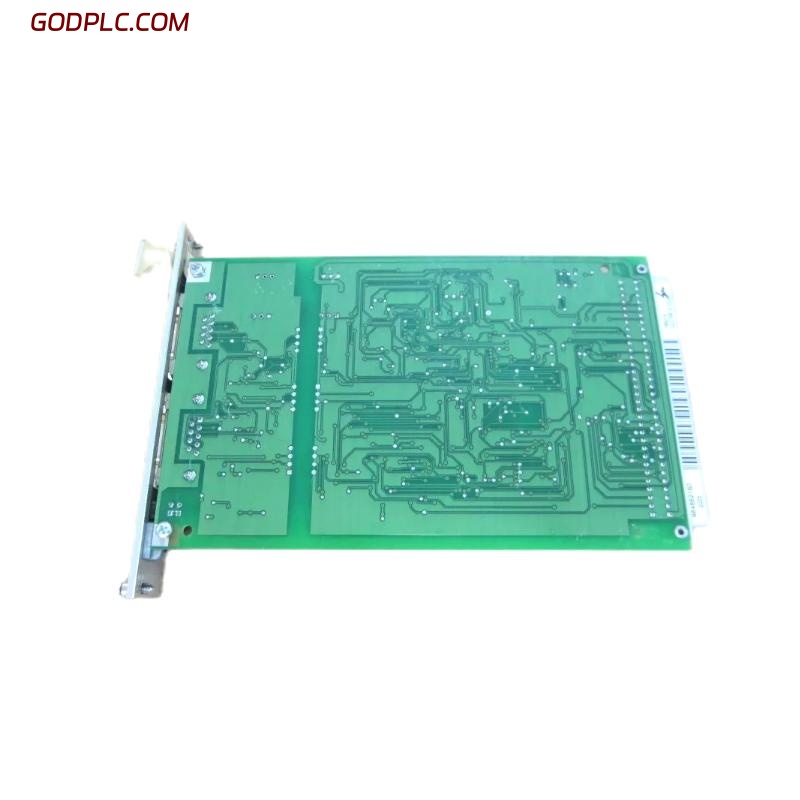

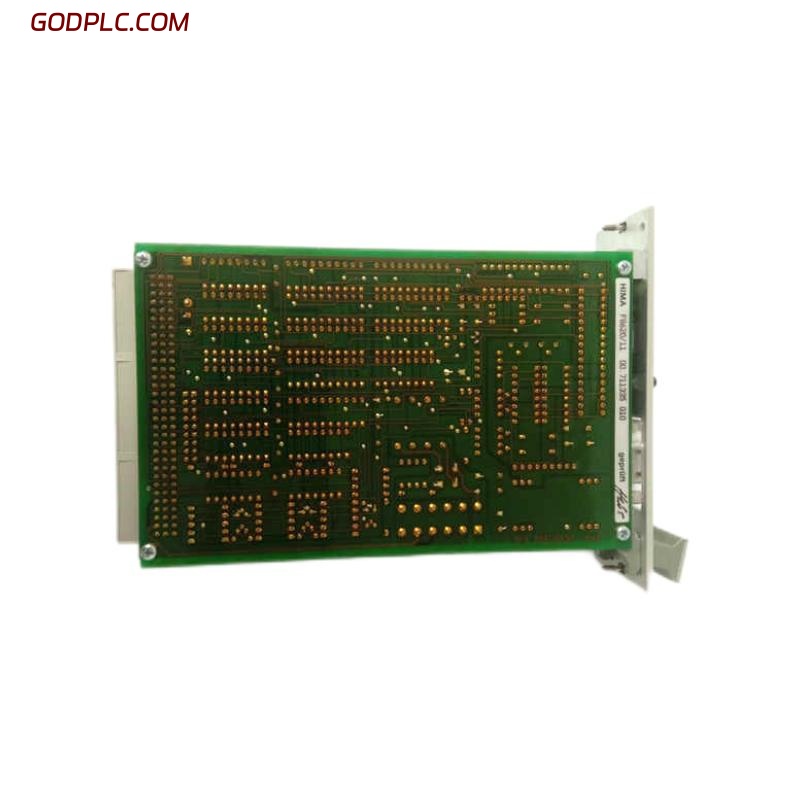

HIMA F8621A Central Processing Unit CPU Module

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

HIMA F8621A Central Processing Unit (CPU) Module

Product Overview

The HIMA F8621A Central Processing Unit (CPU) Module is a core component of HIMA’s safety systems, designed to provide high-performance processing for safety-critical control applications. Engineered for use in industries where safety and reliability are paramount, this CPU module is fully integrated into HIMA’s SIL 3 certified systems, ensuring a robust, fault-tolerant solution for a wide range of industrial applications, including chemical processing, power generation, and oil & gas.

With its advanced processing capabilities, the F8621A delivers superior real-time control, enabling seamless operation of complex safety systems. The CPU module ensures efficient processing of safety-related data, provides intelligent diagnostics, and supports a flexible and scalable architecture for diverse automation needs. Its built-in redundancy and self-monitoring features contribute to an unparalleled level of system availability and safety.

Key Features

-

High-Performance Processing – Optimized for real-time control and processing of complex safety logic, ensuring fast decision-making for critical processes

-

SIL 3 Certification – Fully certified for Safety Integrity Level 3 (SIL 3), ensuring compliance with the highest safety standards for industrial automation

-

Redundancy Support – Supports redundant configurations, providing enhanced system reliability and uptime, crucial for mission-critical applications

-

Built-in Diagnostics – Advanced diagnostic capabilities for proactive monitoring and early detection of potential failures, reducing downtime and ensuring system health

-

Flexible Communication – Equipped with multiple communication protocols, including Ethernet and fieldbus options, for easy integration with various control systems and devices

-

Modular Design – The modular architecture allows for scalable and adaptable system configurations, making it suitable for both small and large installations

-

Wide Environmental Tolerance – Designed to operate effectively in harsh industrial environments, with a broad range of operating temperatures and robust build quality

-

Seamless Integration – Easily integrates with other HIMA modules and third-party systems, offering scalability and future-proofing for long-term system expansion

Technical Specifications

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | 200 x 100 x 50 mm |

| Weight | 1.2 kg |

3.2 Electrical Characteristics

| Item | Specification |

|---|---|

| Input Voltage | 24 VDC ±20% |

| Power Consumption | Approx. 5 W |

| Processor Type | Dual-core Processor |

| Communication | Ethernet, Fieldbus (optional) |

| Redundancy | Support for CPU and power supply redundancy |

| Internal Memory | 512 MB RAM, 2 GB Flash |

3.3 Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 0%–95% RH (non-condensing) |

| Enclosure Rating | IP20 |

3.4 System Compatibility

| Item | Specification |

|---|---|

| System Compatibility | Compatible with HIMA Safety Systems |

| Integration | Supports integration with HIMA Safety Designer for configuration and diagnostics |

Industry Applications

-

Chemical Processing – Provides high-performance control for safety systems monitoring chemical reactors, distillation columns, and hazardous materials handling

-

Oil & Gas – Ensures reliable, real-time processing for critical safety systems in upstream and downstream applications, including drilling rigs, refineries, and offshore platforms

-

Power Generation – Supports advanced control systems for power plant turbines, boilers, and safety shutdown systems, ensuring continuous operation and safe performance

-

Pharmaceuticals – Monitors sensitive pharmaceutical manufacturing processes where safety and accuracy are crucial for regulatory compliance

-

Food & Beverage – Used in safety-critical applications such as automated packaging lines, where uptime and safety are essential

-

Automated Safety Systems – Serves as the central processing unit for automated safety systems in various industries, providing fault tolerance, data integrity, and high availability

The HIMA F8621A Central Processing Unit (CPU) Module is a powerful and reliable choice for critical industrial applications requiring high-performance processing, redundancy, and strict safety standards. Its SIL 3 certification and advanced diagnostic capabilities ensure that it can meet the demands of safety-critical control systems while offering the flexibility and scalability needed for complex automation tasks. Whether integrated into HIMA’s safety systems or in third-party control systems, the F8621A provides the stability and security necessary for a wide range of industries.

HIMA F8621A Central Processing Unit CPU Module is in stock. Please contact us for a quick quote and competitive pricing.

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Company Introduction

Xiamen Shengruite Trading Co., Ltd. is a company specializing in the supply of industrial PLC spare parts.

We provide high-quality PLC spare parts to customers in the global manufacturing, energy and power, chemical and other fields.

Since its establishment in 2011, after 13 years of rapid development, the cumulative global shipments have reached 223,650 pieces, with an annual output value of US$50 million.

Successfully served more than 500 customers in more than 100 countries and regions including Saudi Arabia, UAE, the United States, Europe, Africa, and Southeast Asia

Our Mission

Provide customers with the best quality PLC spare parts and the fastest delivery service to ensure that their industrial automation systems are always in the best operating condition.

We provide a 1-year warranty service, and we support returns and exchanges for any issues to ensure your rights and interests are fully protected.

We can provide detailed product images upon request, and our team can arrange warehouse photos for confirmation to ensure you have all the information you need before making a purchase.

Shipping times vary depending on your location. With the support of our 16 global warehouses, we strive to deliver orders as quickly as possible. Contact us to get an estimated delivery time for your specific location.

The minimum order quantity (MOQ) is typically one unit. However, for larger orders, please contact us for potential discounts and pricing details.

Yes, we offer competitive pricing for bulk purchases. Please reach out to our sales team with the specifics of your order to receive a custom quote.

We accept various payment methods for wholesale orders, including bank transfers (T/T), letters of credit, and other options upon agreement. For large transactions, please contact us directly for payment terms.

Yes, we offer flexible ordering options for both small and large quantities. Whether you\\\\\\\\\\\\\\\’re looking for a single unit or a large batch, we can accommodate your needs.

We occasionally offer promotional discounts for new wholesale customers. Contact us to learn more about any current offers available for first-time buyers.

If you are unsure of compatibility with your existing setup please provide your system details and our support team can verify compatibility prior to purchase.

Returns are accepted within 30 days if the product is unused, unopened, and in its original packaging. Please note that return shipping and associated costs are the buyer\\\\\\\\\\\\\\\’s responsibility.

Yes, we offer technical support for the installation and integration of our products. Our team can assist with setup, configuration, and troubleshooting to ensure a smooth installation.