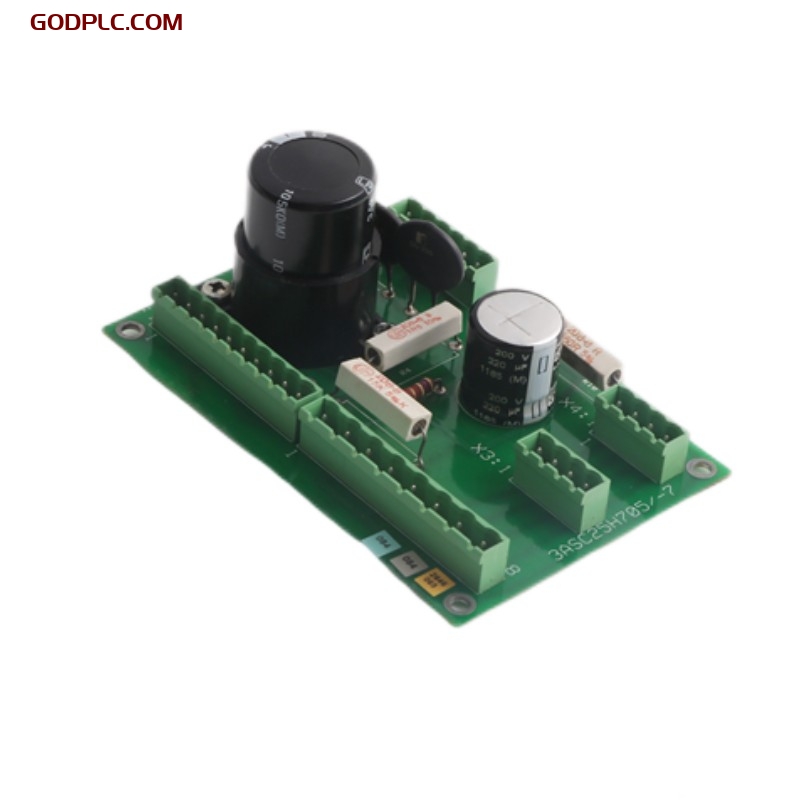

ABB DASA110 3ASC25H705/7 Advanced Controller

Product Overview

The ABB DASA110 3ASC25H705/7 Advanced Controller is a high-performance programmable controller designed to handle complex control and automation tasks in demanding industrial applications. It is part of the DASA series, offering advanced functionalities to optimize automation processes in industries such as manufacturing, energy, chemical processing, and power generation. This controller integrates seamlessly with other ABB automation solutions, providing a powerful platform for precise, real-time control and monitoring.

The DASA110 is equipped with high-speed processing capabilities and robust connectivity options, making it suitable for controlling various systems, from simple to highly complex machinery and processes. With built-in diagnostic features and a high level of flexibility, it ensures operational efficiency and reliability in both small and large-scale automation systems.

Key Features

-

High-Speed Processing: Capable of handling complex control algorithms in real-time, ensuring optimal system performance.

-

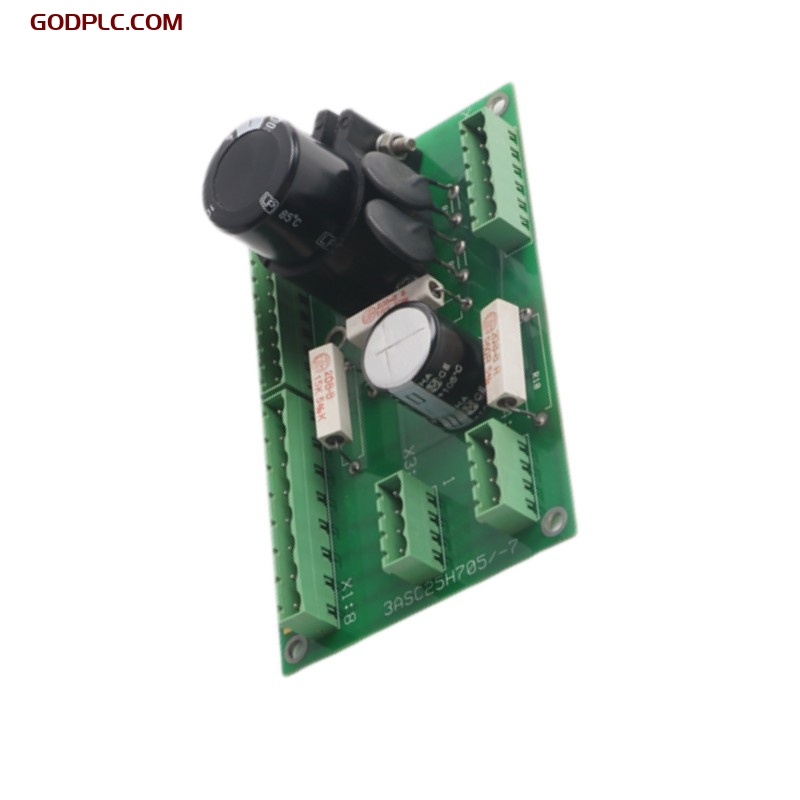

Modular Design: Offers the flexibility to expand and customize the system based on the application needs, with support for various input/output modules.

-

Advanced Communication Capabilities: Supports multiple communication protocols, enabling seamless integration with other ABB devices and third-party systems.

-

User-Friendly Interface: Features an intuitive interface for easy configuration, monitoring, and diagnostics, enhancing usability for operators.

-

Enhanced Diagnostics: Provides comprehensive self-diagnostics and troubleshooting capabilities, helping to minimize downtime.

-

Reliable and Durable: Designed for operation in harsh industrial environments, ensuring continuous and stable performance even in challenging conditions.

-

Compliant with Industry Standards: Meets relevant safety, environmental, and operational standards for industrial automation systems.

Technical Specifications

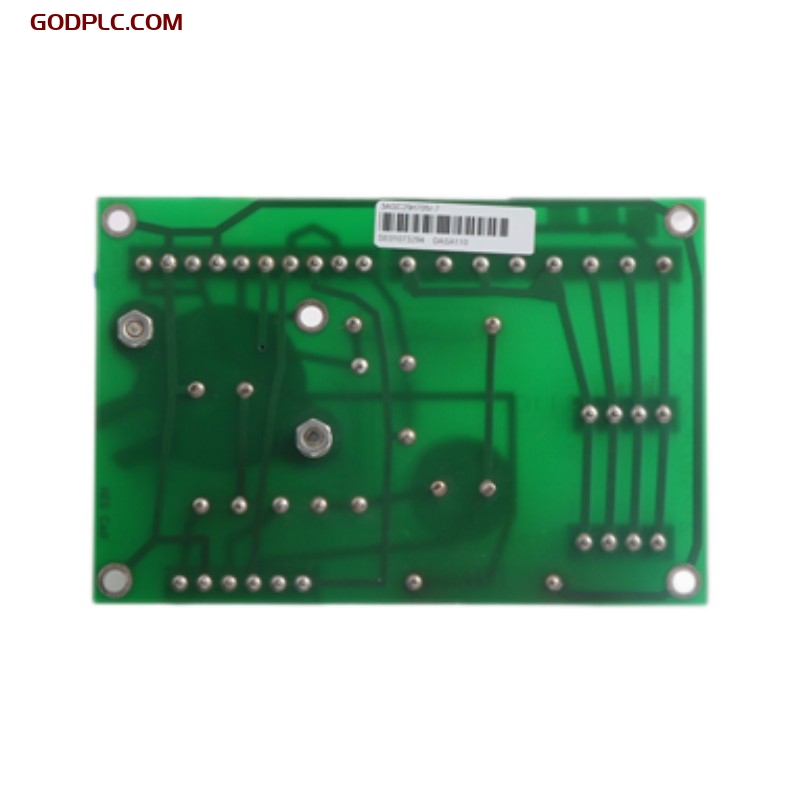

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | 126 x 84 x 50 mm |

| Weight | 0.14 kg |

3.2 Electrical Characteristics

| Item | Specification |

|---|---|

| Voltage Range | 24 V DC |

| Power Consumption | Approx. 15 W |

| Input Power | 24 V DC (nominal), max 30 V DC |

| Output Power | 24 V DC |

3.3 Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temp | -20°C to +60°C |

| Storage Temp | -40°C to +85°C |

| Humidity Range | 5% to 95% RH, non-condensing |

| Protection Class | IP20 |

3.4 Communication and I/O

| Item | Specification |

|---|---|

| Supported Protocols | Ethernet/IP, Modbus TCP/IP, Profibus, CANopen |

| I/O Modules | Compatible with ABB I/O modules for analog, digital, and specialty signals |

| Communication Ports | Ethernet, Serial |

Industry Applications

-

Manufacturing: Ideal for controlling automated production lines, robotic systems, and quality control processes in manufacturing plants.

-

Energy and Power Generation: Used for real-time monitoring and control of power plants, turbines, and energy distribution systems to enhance efficiency and safety.

-

Chemical Processing: Suitable for controlling complex chemical reaction processes, mixing systems, and batch production processes.

-

Oil & Gas: Supports control and monitoring of pumping systems, refineries, and offshore platforms, ensuring safe and efficient operations.

-

Water and Wastewater Treatment: Manages pumps, valves, flow meters, and chemical dosing systems in water treatment plants.

The ABB DASA110 3ASC25H705/7 Advanced Controller provides powerful processing capabilities and versatile communication options, making it an ideal solution for industries requiring high-level control and automation. Its modular design, robust diagnostics, and compatibility with a wide range of I/O modules ensure that it can meet the diverse needs of modern industrial systems, from manufacturing and energy to chemical processing and wastewater management. Its ability to deliver reliable and real-time control makes it an essential tool for optimizing operations and improving efficiency in complex industrial environments.