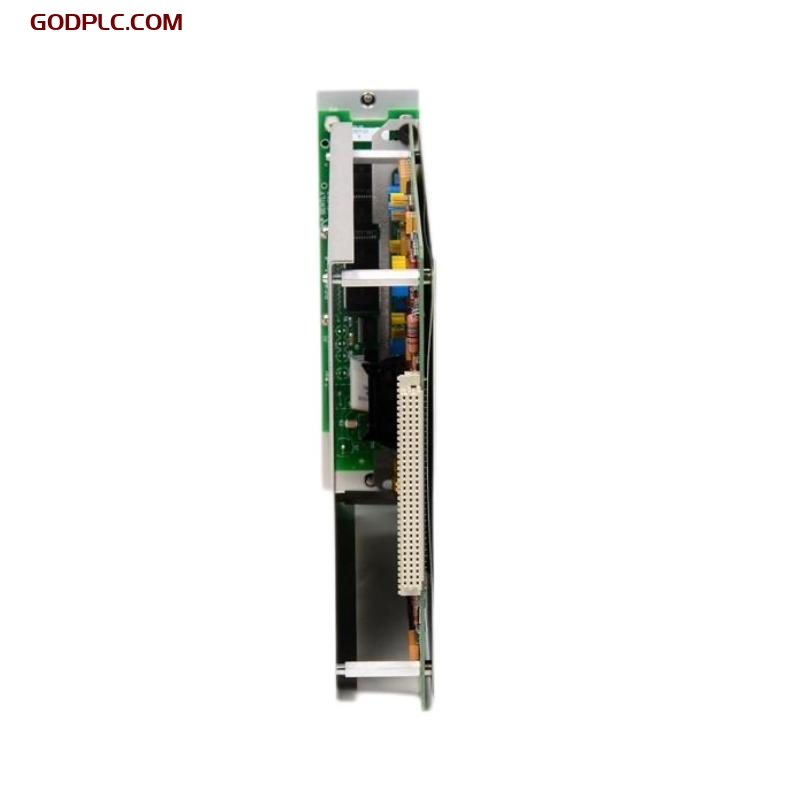

Bently Nevada 3300/16-01-02-01-00-00-00 XY/Gap Dual Vibration Monitor

Product Overview

The Bently Nevada 3300/16-01-02-01-00-00-00 XY/Gap Dual Vibration Monitor is a sophisticated device designed for continuous monitoring of vibration and displacement in industrial machinery. It utilizes dual-axis (XY) vibration and gap measurement technology to offer a complete analysis of rotating equipment, such as motors, turbines, and pumps. This monitor is engineered to provide highly accurate, real-time data essential for early fault detection, helping to avoid equipment failures and reduce maintenance costs. Its robust design makes it suitable for operation in harsh industrial environments, and it is widely used in industries like power generation, oil and gas, and manufacturing.

Key Features

-

Dual Vibration and Gap Monitoring – Offers both XY vibration measurements and gap measurements, allowing for a comprehensive analysis of machine health, including misalignment, imbalance, and axial displacement

-

Precision Measurement – Delivers highly accurate vibration and gap readings, ensuring precise detection of even the most subtle changes in machine conditions

-

Real-Time Data Acquisition – Provides continuous, real-time monitoring to detect issues immediately and enable prompt corrective actions, reducing the risk of unplanned downtime

-

Advanced Diagnostics – Features advanced diagnostic capabilities that support predictive maintenance, allowing for better planning of maintenance activities and extending the lifespan of critical equipment

-

Easy Integration – Designed to integrate seamlessly with Bently Nevada 3300 series monitoring systems, facilitating streamlined operation and data collection

-

Industrial-Grade Durability – Built to perform reliably in demanding environments, including high vibration and temperature conditions, ensuring continuous operation with minimal maintenance needs

-

User-Friendly Interface – Simple interface for quick setup and ease of monitoring, with intuitive data visualization to simplify troubleshooting and decision-making processes

Technical Specifications

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | Vertical size 83 mm |

| Weight | 1 kg |

3.2 Electrical Characteristics

| Item | Specification |

|---|---|

| Input Voltage | 24 VDC (nominal) |

| Power Consumption | Approx. 10 W |

| Output Voltage | 24 VDC (regulated) |

| Output Current | 1 A max |

| Protection | Overload, short-circuit, and surge protection |

3.3 Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temp | -40°C to +70°C |

| Storage Temp | -40°C to +85°C |

| Humidity | 5%–95% RH (non-condensing) |

| Vibration | IEC 60068-2 compliant |

| Protection | IP20 (when installed in an enclosure) |

3.4 System Compatibility

| Item | Specification |

|---|---|

| Platform | Bently Nevada 3300 Series |

| Configuration Tools | Bently Nevada System 1, 3500 Monitoring System |

Industry Applications

-

Power Generation – Monitors critical equipment such as turbines, generators, and motors, providing real-time analysis of vibration and displacement to detect potential failures before they lead to system downtime

-

Oil & Gas – Used in offshore and onshore rigs, compressors, and other critical equipment to continuously monitor machinery and prevent unanticipated failures in high-stakes environments

-

Manufacturing – Monitors high-speed rotating machinery in manufacturing plants to identify signs of misalignment, imbalance, or bearing wear, enabling preemptive maintenance to avoid costly downtime

-

Chemical Processing – Monitors pumps, compressors, and other equipment in chemical processing plants, ensuring smooth operations and early detection of issues that could impact production

-

Water & Wastewater – Provides essential monitoring of pumps and motors in water treatment facilities, enabling operators to detect faults early and avoid disruptions in service

The Bently Nevada 3300/16-01-02-01-00-00-00 XY/Gap Dual Vibration Monitor is designed to offer enhanced monitoring of machine health, combining dual-axis vibration and gap measurements to ensure accurate condition monitoring for rotating machinery. With its real-time data collection, precise measurements, and advanced diagnostics, it allows industries to optimize machine performance, reduce unplanned downtime, and extend equipment life. Whether in power generation, oil and gas, manufacturing, or chemical processing, the 3300 XY/Gap monitor delivers unparalleled performance in harsh and demanding environments.