Bently Nevada 3300/45-03-02-00-00 Dual Differential Pressure Expansion Monitor

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

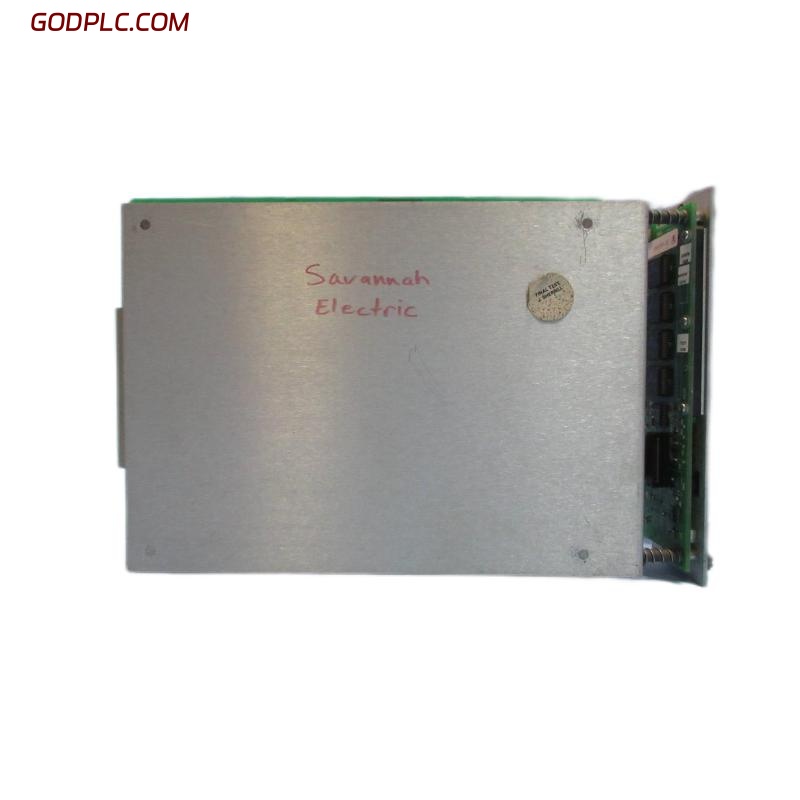

Bently Nevada 3300/45-03-02-00-00 Dual Differential Expansion Monitor

Product Overview

The Bently Nevada 3300/45-03-02-00-00 Dual Differential Expansion Monitor is a specialized monitoring module used in the 3300 Series machinery protection system. It provides dual-channel differential expansion measurement, designed to monitor the relative thermal growth between a machine’s rotor and its stationary casing. This capability is critical for large turbines and compressors where excessive differential expansion can indicate alignment issues or thermal distortion. The module supports API 670 compliance and integrates seamlessly with proximity transducers to provide high-accuracy, real-time monitoring and protection.

Key Features

-

Dual independent differential expansion channels

-

Configurable Alert and Danger thresholds per channel

-

4–20 mA proportional transmitter output

-

LED indicators for OK, Alert, and Danger status

-

Compatible with 3300 XL proximity probe systems

-

API 670 compliant for turbine monitoring systems

-

Easily integrated into 3300 series racks

Technical Specifications

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | Vertical size 83 mm |

| Weight | 1 kg |

3.2 Electrical Characteristics

| Item | Specification |

|---|---|

| Channels | 2 independent measurement channels |

| Sensor Input | 3300 XL Proximity Probe and Extension Cable |

| Input Range | -24 V to -10 V DC bias, ±2 mm dynamic range |

| Measurement Type | Shaft-to-casing axial differential movement |

| Accuracy | ±0.05 mm or ±5% of full scale, whichever is greater |

| Output Signal | 4–20 mA DC, isolated, per channel |

| Relays | OK, Alert, and Danger relays per channel |

| Power Supply | Via 3300 Series Rack |

3.3 Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temp | 0°C to +65°C |

| Storage Temp | -40°C to +85°C |

| Humidity | 5%–95% RH, non-condensing |

| Compliance | Meets API 670 Standard |

3.4 System Compatibility

| Item | Specification |

|---|---|

| System Platform | Bently Nevada 3300 Series Rack |

| Installation | Rack-mounted plug-in module |

| Configuration | Field-configurable via Bently software |

Industry Applications

-

Steam Turbines – Shaft thermal expansion monitoring in power plants

-

Compressors – Monitoring differential movement in axial compressors

-

Petrochemical Equipment – High-temperature machinery expansion analysis

-

Gas Turbines – Ensuring safe alignment during startup and operation

-

Rotating Machinery – Broad application in critical rotating assets

The Bently Nevada 3300/45-03-02-00-00 Dual Differential Expansion Monitor provides reliable, high-resolution expansion monitoring, ensuring optimal alignment, machinery protection, and API compliance for critical rotating equipment.

Bently Nevada 3300/45-03-02-00-00 Dual Differential Pressure Expansion Monitor is in stock. Please contact us for a quick quote and competitive pricing.

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Company Introduction

Xiamen Shengruite Trading Co., Ltd. is a company specializing in the supply of industrial PLC spare parts.

We provide high-quality PLC spare parts to customers in the global manufacturing, energy and power, chemical and other fields.

Since its establishment in 2011, after 13 years of rapid development, the cumulative global shipments have reached 223,650 pieces, with an annual output value of US$50 million.

Successfully served more than 500 customers in more than 100 countries and regions including Saudi Arabia, UAE, the United States, Europe, Africa, and Southeast Asia

Our Mission

Provide customers with the best quality PLC spare parts and the fastest delivery service to ensure that their industrial automation systems are always in the best operating condition.

We provide a 1-year warranty service, and we support returns and exchanges for any issues to ensure your rights and interests are fully protected.

We can provide detailed product images upon request, and our team can arrange warehouse photos for confirmation to ensure you have all the information you need before making a purchase.

Shipping times vary depending on your location. With the support of our 16 global warehouses, we strive to deliver orders as quickly as possible. Contact us to get an estimated delivery time for your specific location.

The minimum order quantity (MOQ) is typically one unit. However, for larger orders, please contact us for potential discounts and pricing details.

Yes, we offer competitive pricing for bulk purchases. Please reach out to our sales team with the specifics of your order to receive a custom quote.

We accept various payment methods for wholesale orders, including bank transfers (T/T), letters of credit, and other options upon agreement. For large transactions, please contact us directly for payment terms.

Yes, we offer flexible ordering options for both small and large quantities. Whether you\\\\\\\\\\\\\\\’re looking for a single unit or a large batch, we can accommodate your needs.

We occasionally offer promotional discounts for new wholesale customers. Contact us to learn more about any current offers available for first-time buyers.

If you are unsure of compatibility with your existing setup please provide your system details and our support team can verify compatibility prior to purchase.

Returns are accepted within 30 days if the product is unused, unopened, and in its original packaging. Please note that return shipping and associated costs are the buyer\\\\\\\\\\\\\\\’s responsibility.

Yes, we offer technical support for the installation and integration of our products. Our team can assist with setup, configuration, and troubleshooting to ensure a smooth installation.