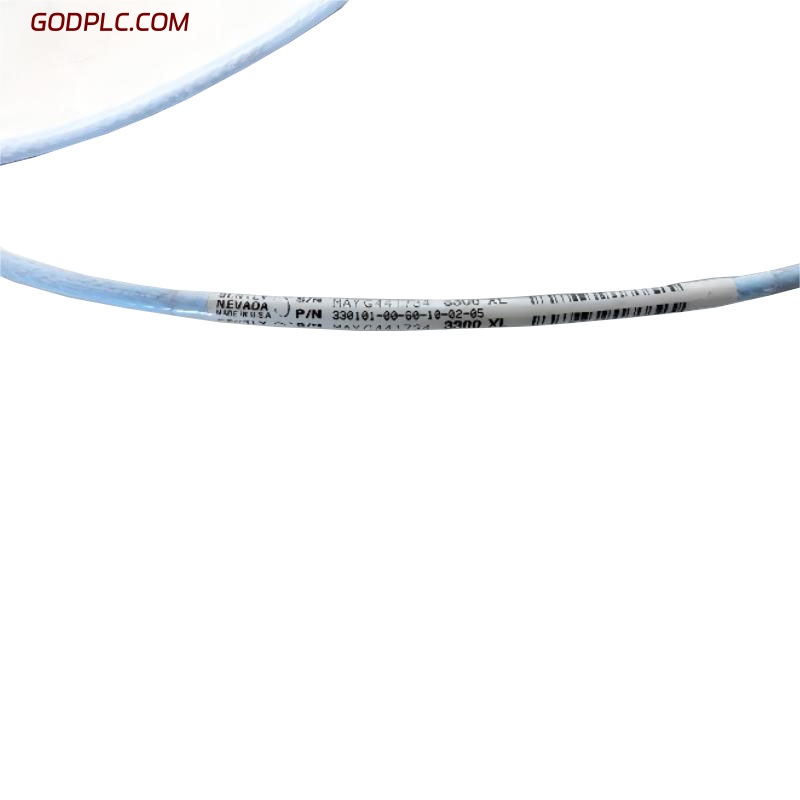

Bently Nevada 330500-03-00 Velomitor Piezoelectric Velocity Sensor

Product Overview

The Bently Nevada 330500-03-00 Velomitor Piezoelectric Velocity Sensor is a high-performance vibration sensor specifically designed to measure the velocity of machinery vibrations. This sensor is part of the Velomitor series and is optimized for use in industrial environments where precise vibration measurement is critical for condition monitoring and predictive maintenance. It is engineered to provide accurate real-time velocity data for monitoring the health of rotating equipment such as motors, pumps, compressors, and turbines. Its piezoelectric design ensures high sensitivity to vibration across a wide frequency range, making it an ideal solution for detecting early signs of mechanical issues.

Key Features

-

Piezoelectric Technology: Utilizes piezoelectric crystals to generate a high-sensitivity electrical signal in response to vibration, providing precise and reliable velocity measurements.

-

Wide Frequency Range: Capable of accurately measuring vibrations across a broad frequency spectrum, from low to high frequencies, ensuring comprehensive monitoring of machinery health.

-

High Sensitivity: Offers excellent sensitivity to low vibration levels, enabling early detection of mechanical faults like imbalance, misalignment, and bearing wear.

-

Durable and Robust Construction: Designed for use in harsh industrial environments, the sensor is built to withstand high vibration, extreme temperatures, and other challenging conditions.

-

Easy Installation: Compact and lightweight, the Velomitor sensor is easy to install in tight spaces and integrates seamlessly into Bently Nevada’s machinery condition monitoring systems.

-

Low Maintenance: With no moving parts, the piezoelectric design offers long-term reliability and requires minimal maintenance, reducing overall downtime.

-

Environmentally Protected: With a robust housing and environmental protection, the sensor is resistant to dust, moisture, and contaminants, ensuring dependable performance in tough industrial conditions.

Technical Specifications

3.1 Dimensions and Weight

| Item | Specification |

|---|---|

| Diameter | Diameter 25.3 mm |

| Weight | 0.142 kg |

3.2 Module Information

| Item | Specification |

|---|---|

| Model Number | 330500-03-00 |

| Sensor Type | Piezoelectric Velocity Sensor |

| Mounting | Standard mounting via threaded housing |

| Material | Stainless steel (sensor body) |

3.3 Electrical and Physical Characteristics

| Item | Specification |

|---|---|

| Measurement Type | Velocity (mm/s) |

| Frequency Range | 0.1 Hz to 10 kHz |

| Sensitivity | 1.0 mV/(mm/s) |

| Temperature Range | -40°C to +120°C |

| Output | 4-20 mA or Voltage Output |

| Protection Class | IP68 |

3.4 System Compatibility

| Item | Specification |

|---|---|

| Compatible System | Bently Nevada Monitoring Systems |

| Communication Interface | 4-20 mA or Voltage output |

| Software Configuration | Bently Nevada System 1, Monitoring System 3500 |

Industry Applications

-

Turbomachinery Monitoring: Used for condition monitoring of critical turbines, compressors, and generators in power plants and industrial settings, providing real-time vibration data for early fault detection.

-

Pump and Motor Monitoring: Ideal for detecting issues in pumps, motors, and other rotating equipment, helping to identify problems such as misalignment, bearing wear, or imbalance before they lead to failure.

-

Condition-Based Monitoring: Part of a predictive maintenance system, offering real-time vibration velocity measurements that help operators schedule maintenance proactively and avoid costly unplanned downtime.

-

Oil & Gas: Applied in offshore platforms and refineries, providing vital data for the maintenance of high-speed rotating equipment in harsh conditions.

-

Petrochemical and Chemical Processing: Ensures the smooth operation of critical machinery by monitoring vibration velocity and identifying potential issues in rotating equipment before they cause significant damage.

-

Manufacturing Automation: Helps improve equipment reliability in manufacturing plants by continuously monitoring the condition of machinery such as motors, pumps, and conveyors.

-

Mining: Used in mining operations to monitor crushers, mills, and other equipment, preventing breakdowns and ensuring optimal performance.

The Bently Nevada 330500-03-00 Velomitor Piezoelectric Velocity Sensor is an essential tool for vibration-based condition monitoring in rotating machinery. Its high sensitivity, broad frequency range, and durable construction make it an ideal choice for industries requiring accurate, real-time velocity data to ensure the health and reliability of their equipment.