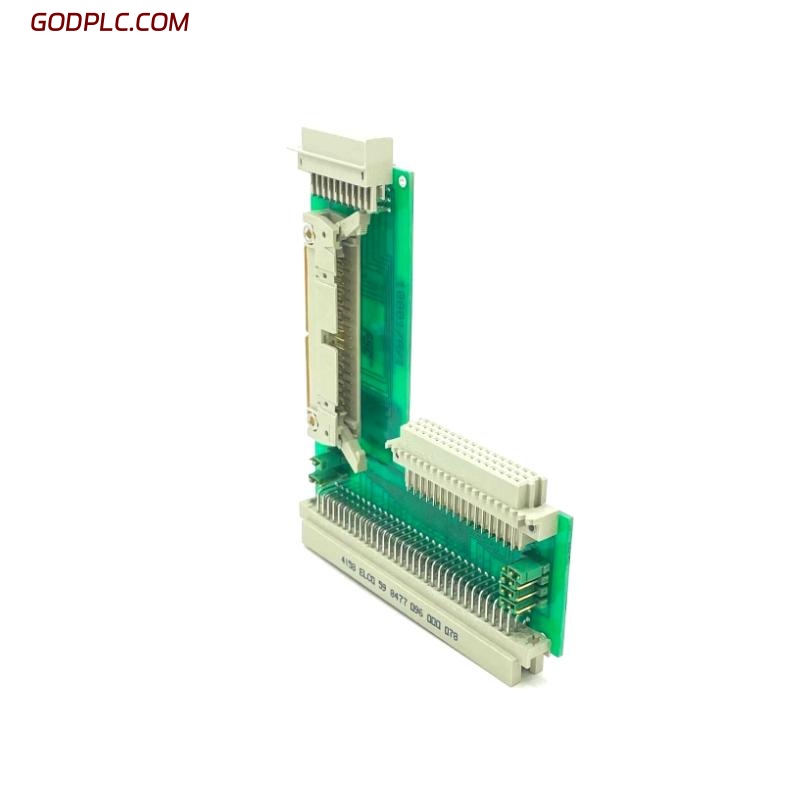

Honeywell 10001/A/1 Vertical Bus Driver Module

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Honeywell 10001/A/1 Vertical Bus Driver Module

Product Overview

The Honeywell 10001/A/1 Vertical Bus Driver Module is an essential component designed for high-performance data communication within Honeywell’s industrial automation systems. It provides reliable and fast communication between the central processing units (CPUs) and other modules connected within the system, ensuring smooth and efficient data transmission across the entire network. This module plays a crucial role in enabling the operation of distributed control systems (DCS), allowing for precise monitoring and control of various processes in industries such as manufacturing, oil & gas, power generation, and chemical processing.

The Vertical Bus Driver Module is engineered to maintain optimal communication integrity even in demanding industrial environments. It supports robust data transfer rates and ensures real-time communication with high reliability, making it an ideal solution for mission-critical applications where uptime and continuous data flow are crucial.

Key Features

-

High-Speed Data Transfer – Designed for high-speed communication, enabling rapid data exchange between the CPU and other system modules.

-

Reliability – Provides robust, uninterrupted data transmission even in environments with high electrical noise or vibration, ensuring system reliability.

-

Vertical Bus Architecture – Compatible with Honeywell’s modular control systems, utilizing a vertical bus architecture to optimize signal integrity and reduce communication latency.

-

Scalable and Flexible – Easily scalable to meet the growing needs of industrial control systems, supporting the addition of new modules and devices without compromising performance.

-

Integration with Honeywell Systems – Seamlessly integrates with Honeywell’s Experion® PKS, ControlEdge, and other industrial automation platforms, ensuring compatibility and smooth operation across diverse systems.

-

Durable and Industrial-Grade – Built to withstand harsh industrial environments, including temperature fluctuations, high humidity, and exposure to contaminants.

-

Enhanced Diagnostic Capabilities – Includes built-in diagnostic features to detect potential issues, helping to reduce system downtime and simplify troubleshooting.

Technical Specifications

Dimensions and Weight

| Item | Specification |

|---|---|

| Dimensions | 160 x 120 x 25 mm |

| Weight | 0.15 kg |

Electrical Characteristics

| Item | Specification |

|---|---|

| Input Voltage | 24 VDC ±20% |

| Power Consumption | Approx. 3 W |

| Data Transfer Rate | 100 Mbps (typical) |

| Communication Protocol | Vertical Bus, Ethernet, Fieldbus |

Environmental Characteristics

| Item | Specification |

|---|---|

| Operating Temperature | -10°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% RH (non-condensing) |

| Vibration Resistance | 2 g (constant) |

| Enclosure Rating | IP20 (dust-tight) |

System Compatibility

| Item | Specification |

|---|---|

| Compatible Systems | Honeywell Experion® PKS, ControlEdge |

| Integration | Integrates with Honeywell’s automation platforms and control modules |

Industry Applications

-

Manufacturing Automation – Facilitates communication across production lines, providing real-time data transfer to ensure smooth and efficient operations.

-

Power Generation – Supports critical communication in power plants, ensuring that data flows seamlessly between generators, turbines, and control systems to maintain stability and efficiency.

-

Chemical Processing – Enables real-time communication for process control in chemical plants, improving safety and optimizing production.

-

Oil & Gas – Plays a crucial role in ensuring reliable communication between distributed control systems (DCS) in refineries, pipelines, and offshore platforms.

-

Water and Wastewater Treatment – Helps maintain communication between sensors, pumps, and control systems, ensuring continuous and reliable water treatment processes.

-

Building Automation – Facilitates the integration of HVAC systems, lighting, security, and energy management systems in large-scale building management systems (BMS).

-

Transportation – Used in transportation systems, such as railway or airport control centers, to ensure real-time data transfer for smooth operations and safety management.

The Honeywell 10001/A/1 Vertical Bus Driver Module is a critical component for ensuring high-speed, reliable data communication in Honeywell’s industrial automation systems. With its vertical bus architecture, high-speed data transfer, and robust environmental tolerance, it is ideal for applications where reliable and timely data exchange is essential for maintaining operational efficiency. It integrates seamlessly with Honeywell’s control systems, such as Experion® PKS and ControlEdge, and is built to handle the challenges of demanding industrial environments.

Honeywell 10001/A/1 Vertical Bus Driver Module is in stock. Please contact us for a quick quote and competitive pricing.

| Company Information | ||||||||

| sales@industrial88.com | ||||||||

| Mobile | +8617350837383 | |||||||

| +8617350837383 | ||||||||

| 17350837383 | ||||||||

| Add to | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Company Introduction

Xiamen Shengruite Trading Co., Ltd. is a company specializing in the supply of industrial PLC spare parts.

We provide high-quality PLC spare parts to customers in the global manufacturing, energy and power, chemical and other fields.

Since its establishment in 2011, after 13 years of rapid development, the cumulative global shipments have reached 223,650 pieces, with an annual output value of US$50 million.

Successfully served more than 500 customers in more than 100 countries and regions including Saudi Arabia, UAE, the United States, Europe, Africa, and Southeast Asia

Our Mission

Provide customers with the best quality PLC spare parts and the fastest delivery service to ensure that their industrial automation systems are always in the best operating condition.

We provide a 1-year warranty service, and we support returns and exchanges for any issues to ensure your rights and interests are fully protected.

We can provide detailed product images upon request, and our team can arrange warehouse photos for confirmation to ensure you have all the information you need before making a purchase.

Shipping times vary depending on your location. With the support of our 16 global warehouses, we strive to deliver orders as quickly as possible. Contact us to get an estimated delivery time for your specific location.

The minimum order quantity (MOQ) is typically one unit. However, for larger orders, please contact us for potential discounts and pricing details.

Yes, we offer competitive pricing for bulk purchases. Please reach out to our sales team with the specifics of your order to receive a custom quote.

We accept various payment methods for wholesale orders, including bank transfers (T/T), letters of credit, and other options upon agreement. For large transactions, please contact us directly for payment terms.

Yes, we offer flexible ordering options for both small and large quantities. Whether you\\\\\\\\\\\\\\\’re looking for a single unit or a large batch, we can accommodate your needs.

We occasionally offer promotional discounts for new wholesale customers. Contact us to learn more about any current offers available for first-time buyers.

If you are unsure of compatibility with your existing setup please provide your system details and our support team can verify compatibility prior to purchase.

Returns are accepted within 30 days if the product is unused, unopened, and in its original packaging. Please note that return shipping and associated costs are the buyer\\\\\\\\\\\\\\\’s responsibility.

Yes, we offer technical support for the installation and integration of our products. Our team can assist with setup, configuration, and troubleshooting to ensure a smooth installation.